Welcome to April 2024 edition of the XIIth volume of Carnival of Quality Management Articles and Blogs.

The theme for the XIIth volume of our Carnival of Quality Management Articles and Blogs is The Defining Trends of Quality Management – Raising The Bar.

For the present episode, we will take up knowledge sharing within and outside the stakeholders.

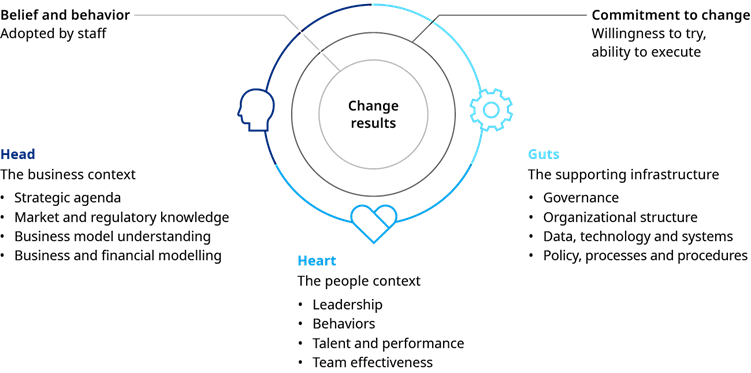

Knowledge sharing is capturing, managing, and distributing key information within an organization.

The gap between what the organization knows and what it needs to know to succeed can be reduced by:

- by encouraging communication between teams and departments.

- By creating central repository for knowledge and best practices whereat the employees document their knowledge and any essential information about their job

- By creating a centralized tool whereat all data is so stored that employees don’t waste time looking for what they need.[1]

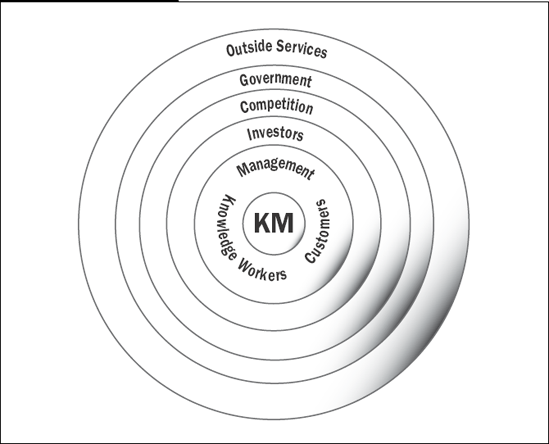

A prerequisite to understanding the economics of Knowledge Management is to define the typical stakeholders in a corporation in the midst of a KM initiative.

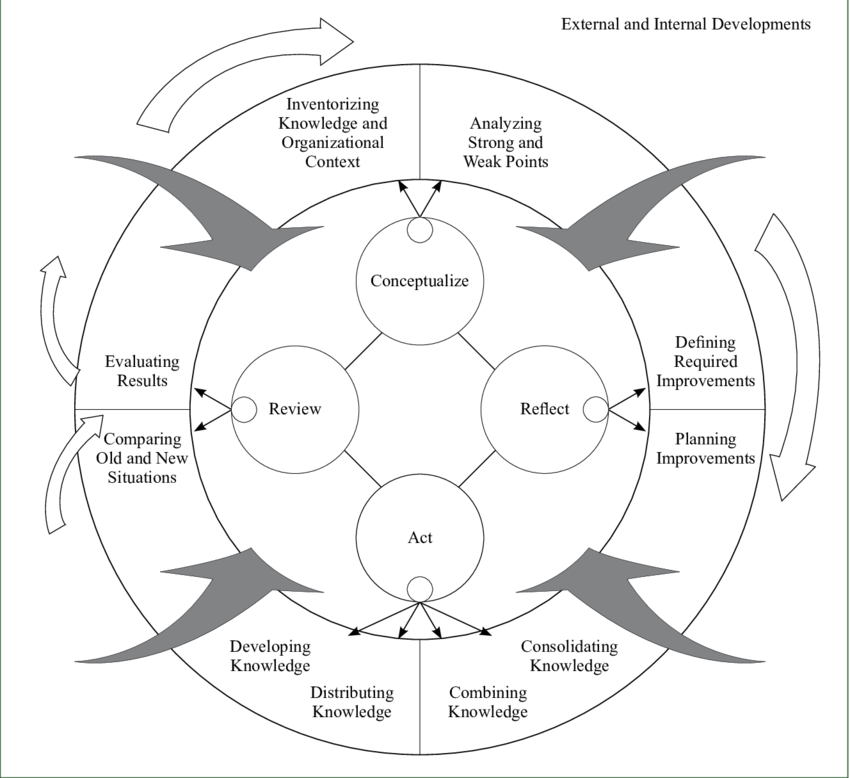

The four levels of knowledge management[2]:

| Level | Activity |

| 1 | Information Management |

| 2 | Knowledge Sharing |

| 3 | Sensemaking, Decision Making & Innovation |

| 4 | Agency and Communityship |

While the difficulty of sharing knowledge is in transferring knowledge from one entity to another, it may prove profitable for organizations to acknowledge the difficulties of knowledge transfer and adopt new knowledge management strategies accordingly

Further reading:

Becoming a knowledge sharing organization

Essentials of Knowledge Management by Bryan Bergeron

The Ultimate Guide to Organizational Knowledge Sharing

Next Level of Knowledge Sharing – Insights from an SME

We now turn to our regular sections.

Finally, we take up the article Lean with Lazarus: Don’t Close the Door on the Most Basic Quality Principles – If the culture in your organization is essentially “do the best you can,” then you really need to take a closer look at these methods – Airplane travel is indeed the safest way to get from point A to point B, with a 1 in 11 million chance of being involved in a fatal crash. But when the chair of the NTSB suggests the airline industry has a “quality control problem,” it’s fair to demand that the industry ensure some of the most fundamental practices are not just acknowledged, but put into practice every day. Here are a few practices that might benefit a process known to produce missing bolts.

Fewer handoffs: Labor intensive processes are already error-prone, and the likelihood of an error increases exponentially when one worker is handing off responsibility to another. Perform a thorough value stream or swim-lane analysis to reveal all the handoffs in your process. Then redesign the process to eliminate or at least minimize them. Solve this problem for the last time.

Error Proofing. Envision a process that is incapable of producing an error, and you have the right mindset to start. In actual practice, the goal is to “make it easy to do the right thing,” and that takes the form of unambiguous job aides, visual controls, and forced functions.

Mindfulness. The purpose of mindfulness is to be in the present moment, free of distractions, with full concentration on the task at hand. Multi-tasking is inconsistent with mindfulness because while computers may be able to multi-task efficiently, human beings cannot. We ultimately sub-optimize most of the activities we are trying to accomplish when we are either multi-tasking, or otherwise not fully present.

Only a relentless quality team can ensure that when it comes to the bolts, they are in the right place, at the right time, and at the right tension.

I look forward to your views / comments / inputs to further enrich the theme of The Defining Trends of Quality Management – Raising The Bar.

Note: The images or video clips depicted here above are through courtesy of respective websites who have the copyrights for the respective images /videos.

The 2023 remained under shadows of uncertainty caused by changing work place culture on account of latent and unforeseen effects of work-from-home practices, fluid global geo-political scenario, recession dominated thinking of the economic issues, etc. These issues remain even more relevant as we enter 2024. The unpredictability continues to define the trend.

The 2023 remained under shadows of uncertainty caused by changing work place culture on account of latent and unforeseen effects of work-from-home practices, fluid global geo-political scenario, recession dominated thinking of the economic issues, etc. These issues remain even more relevant as we enter 2024. The unpredictability continues to define the trend.